Cleargard® polycarbonate safety glazing is a major innovation as a substitute for glass. Its technical qualities are exceptional: resistance to impact and abrasion, remarkable hardness, excellent performance. And above all, optimum optical quality with Cleargard® Opti Plus!

Plastrance, a privileged partner

for the agricultural machinery and safety vehicles industry

PLASTRANCE offers high-performance safety glazing to agricultural market players (tractors and forestry machinery) as well as security transport vehicles. Thanks to its Cleargard® range, it can supply windshields, side windows, rear windows and glass roofs.

Cleargard®, a true break through in safety glazing!

In partnership with some big names in chemical industry, PLASTRANCE has developed an exclusive range of Cleargard® safety glazing made of polycarbonate with an exceptional hardness combining the visual performance of glass (with Cleargard® Opti Plus) and the lightness of thermoplastics.

In the event of severe impacts, Cleargard® Opti Plus safety glazing, flat or thermoformed, does not cause any glare and retains all its optical qualities. Cleargard® glazing is installed on all Police and Gendarmerie vehicles but also on all cabins for agricultural machinery, cabins for construction equipment, forestry and civil engineering.

In addition to the optical quality, Cleargard® has many other advantages:

- Light Stability

- Very good light transmission day and night

- Good resistance to moisture and bad weather

- Does not cause any glare (unlike glass)

- Very good chemical resistance

- Abrasion resistance according to the French standard TPVP and European standard R43/E/ECE/324

- Cleargard® glazing with flat and rounded abrasion-resistant coating is approved by the Ministry of Transport and other European approval organisations.

Cleargard® Opti Plus safety glazing was developed by PLASTRANCE to meet the most stringent international standards, earning aa award at Midest 2011.

Cleargard®, a glazing

twice as light as glass

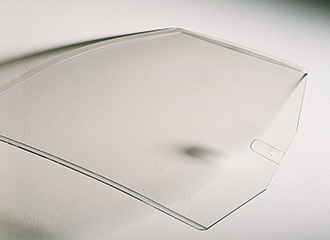

Safety windshield - Polycarbonate - 1650x1050mm

Cleargard® polycarbonate safety glazing helps reduce vehicle weight and can be a serious technical alternative to conventional glass, which is twice as heavy.

Another benefit of the lightness of a vehicle equipped with Cleargard® glass: optimized fuel consumption!

Replace glass

with thermoplastic?

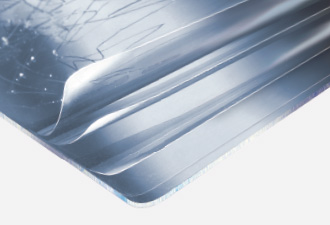

Detail of a screenprinted safety glazing with primisation and coating

Perhaps there will never be complete substitution by thermoplastics. The two materials each retain their specific characteristics that are decisive for the use that will be made of them.

The use of polycarbonate glazing is most appropriate for police and military forces, where visibility and protection during law enforcement operations are of prime importance.

PLASTRANCE abrasion-resistant coatings allow our polycarbonate glazing to resist UV, scratches and extend its life. Our extensive experience and our range of coatings allow us to provide coatings that meet the unique needs of each customer

- Anti-abrasion

- Anti-UV

- Anti-static

- Anti-graffiti

- Anti-misting

The Cleargard® range

is also available in a laminated version

Laminated polycarbonate is formed of two or more sheets of polycarbonate between which are inserted transparent interlayer films, generally PVB plastic nature. It offers a significant improvement in the mechanical strength of the product and a good resistance to UV rays.